last weekend I have finally managed to finish (or almost finish) cleaning my gearbox on the outside, so here are some fresh pictures:

Still only 95% happy with the cleaning status, as some spots are really hard to access and require more work with a small rotary tool, e.g. Dremel or similar. Here are some pictures that show the condition before the cleaning job:

The dry mud crust sometimes sat like concrete on the aluminium housing - really hard to remove! I used mainly small wire brushes (toothbrush size) and other small tools to clean it all manually, since I find that rotary tools tend to leave unwanted structures on the surfaces.

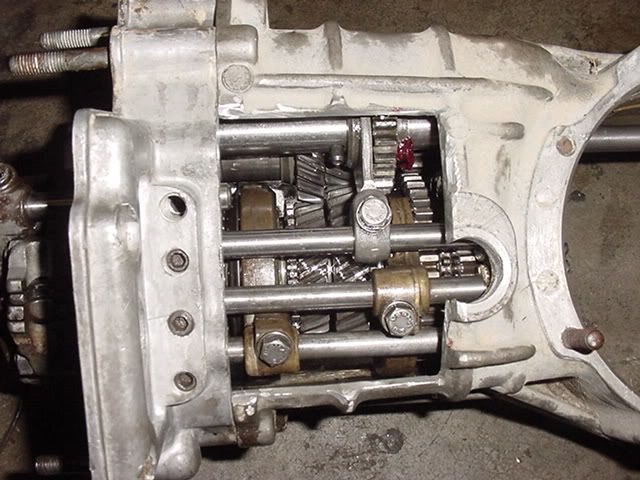

My plan is now to find the correct special tools somewhen this summer to perform a proper overhaul on the inwards - or, if I'm not that lucky, have it done by a specialist in Graz. Meanwhile, I'll keep on cleaning and restoring other parts, such as the half axles, hub gears etc... The central tube is also still on my workbench. I'll keep you posted on the progress, hopefully soon!

Regards,

C.